Note: sources and design files can be found here:

It happens more or less regularly that I find myself in the need for a temperature logger. When I do, I always regret not having something more practical than proto boards, sensors and the usual big question mark on how to gather and then analyze data.

In spite of the fact that I know that there are already solutions out there, definitely more mature than any weekend-job attempt that might never see a revision B, I find “reinventing the wheel” quite charming for learning and refining design and problem-solving processes.

I ended up with a device that could be used for applications such as:

- Long term temperature and environmental data logging

- Datacenter temperature and humidity monitoring

- Reflow controller

- Air quality logger

- Oven calibration (well.. cakes need precision)

- Sous-vide controller

- Ramen broth controller

Even though the primary purpose of the project was, at the end, to write this article and condensing the whole experience into a shareable medium.

The big picture

I started from a set of requirements for this wannabe device:

- support for two thermocouples

- optional support for DS1820 1-wire sensors

- onboard environmental sensor (at least temperature and humidity)

- onboard user interface

- flexible connectivity options: network (ethernet or WiFi) and serial

- output for relays or general purpose actuators, at least 2 channels

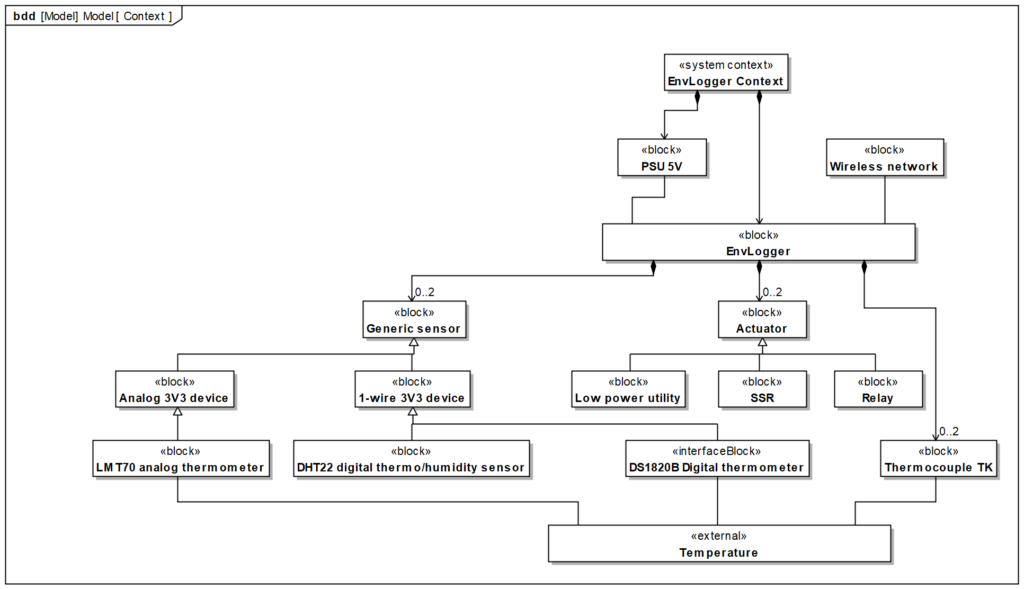

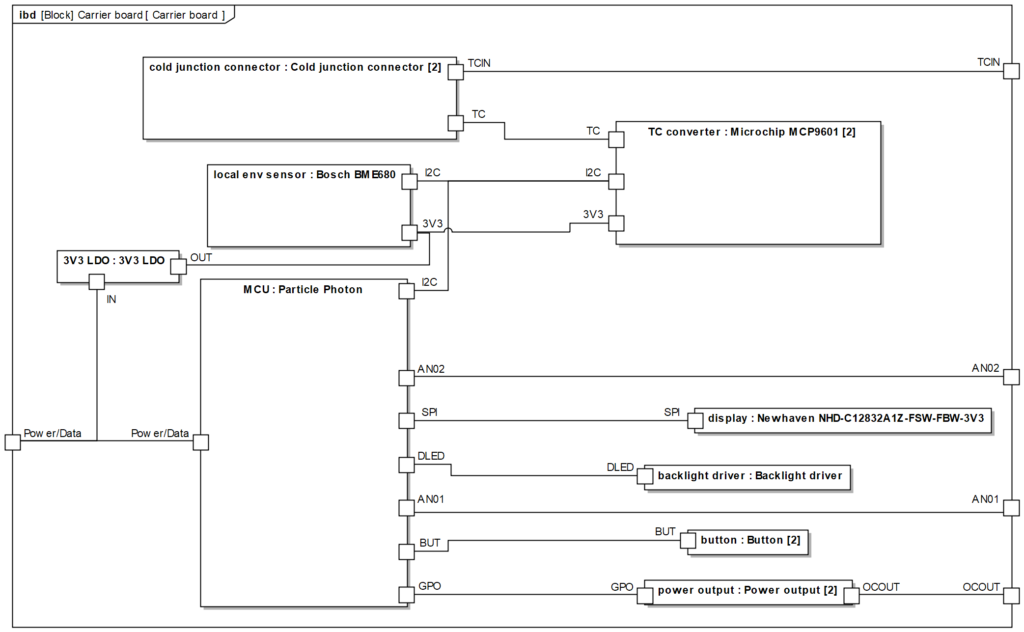

Then I sketched a BDD diagram of the context, describing the interaction between device and the great outdoors.

Thermocouples

My toolset for temperature reading:

- an IR thermometer to sample quickly and on broad, non-shiny measuring targets

- a NWIR camera to sample heat propagation and distribution on a system

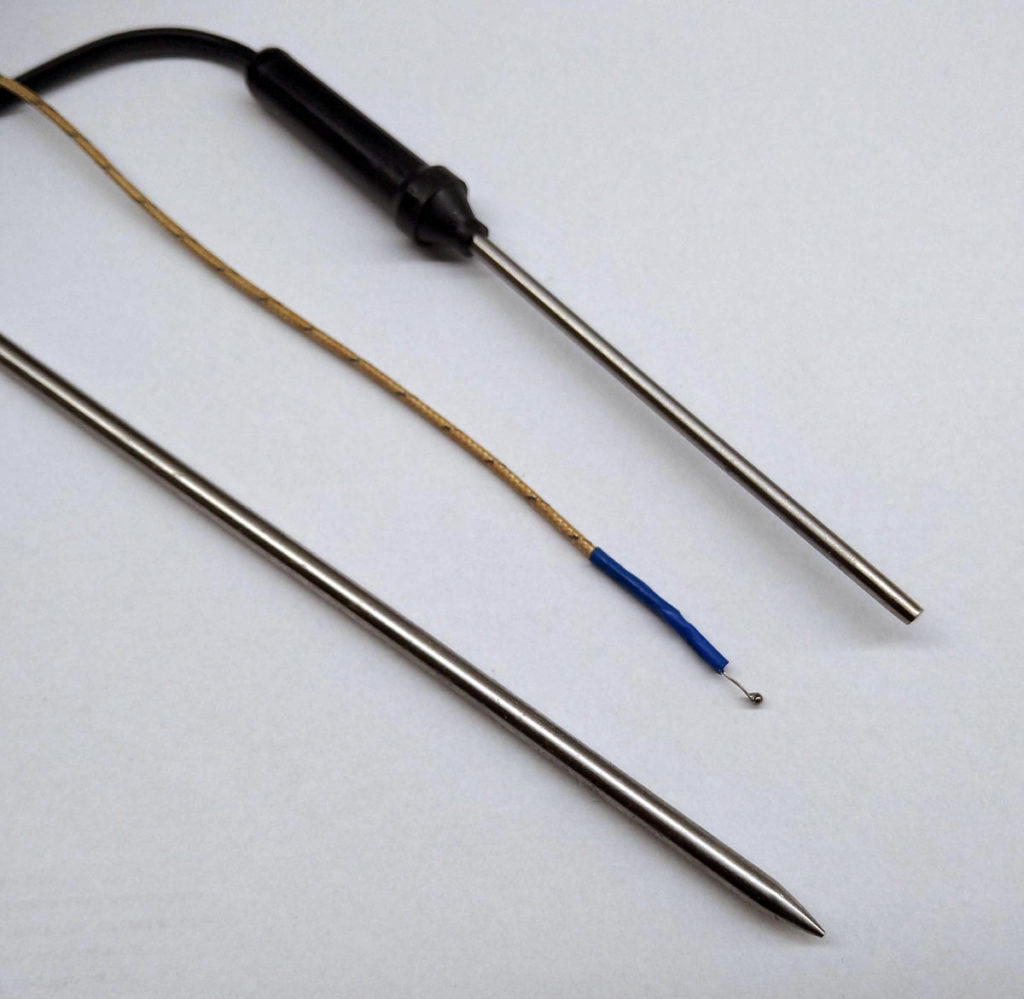

- DS1820B probes for long term, logging tasks

- thermocouples for wide or extreme temperatures

Thermocouples are cheap, fast, easy to obtain and to bind to the target. Since universe is balanced, there’s a con, which is precision. For almost all my task though, ±1C isn’t a big deal.

RTDs are thermocouples’ competitors and increasingly used in industry. They’re more linear, more precise, more slow, and more expensive. But in spite thermocouples to come in many varieties (with balanced pros and cons) and their nasty non-linearities, there are plenty of specialized chips that don’t need anything else than an I2C bus and a proper connection to the cold junction.

So welcome thermocouples. Type K, most common.

Other sensors

As mentioned, using a DS1820B digital thermometer probes happens quite often to me. Adafruit distributes them also in waterproof, (relative) high-temperature case.

These sensors are very easy to integrate since they require only one data pin (Dallas/Maxim 1-wire), plus ground and eventually VCC (unless a special mode called parasite-power is used) and there are libraries for arduino and mbed.

Other types of sensors that require only three pins (including power) are the notorious DHT11 or DHT22 ambient temperature / humidity sensors.

And for another category, this time analog, it is worth mentioning TI LMT70 and TMP36, analog sensors that operates also with 3V3. The more popular LM35 doesn’t work at 3V3.

Actuators

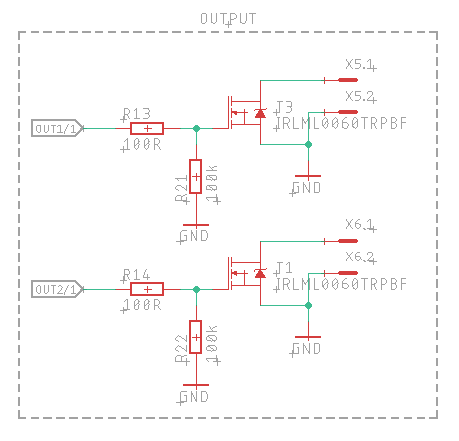

Splatting a couple of MOSFETs as output driver is a no-brainer. Since this unit could be used as a PID controller, having an output stage might come in handy.

Then, let’s add two open-drain outputs.

Connectivity

Ethernet is the only protocol stack that has never let me down.

It has also the advantage, when dealing with low-power devices, to be able to source power via PoE and with chips like WizNet W5500, it’s rather easy to integrate.

The reason why I chose WiFi for this project lays on two relevant points:

- I thought about using Particle’s products, which are heavily wireless-connectivity oriented

- In my typical use case, when ethernet is available, so does WiFi

The reason for the first one is the answer to “what can I do to finally use this dusty protoboard?”. Jokes besides, I like the quality of Particle’s workflow and documentation: they offer a wide variety of options for handling devices and communicating with them. Including a working OTA concept, which is a crucial point for a device that is not directly connected to any host (that can easily push firmware updates to it).

Particle offers development kits and compact modules, such as the P0 (this one in particular for the barest WiFi connectivity).

Since everything I needed was already crammed into a Particle Photon devkit, such as:

- USB connector

- standard LEDs set (RGB + onboard D7)

- setup / reset buttons

- WiFi antenna (and, why not, u.FL connector)

I had to relinquish my crave for minimalism (or maybe I did not) and extra soldering challenges and opted to integrate directly the dev kit onto the board.

So, WiFi, let’s see if I can trust you.

One layer below

So far I described the process to evaluate requirements starting from the outside world’s context, with some digressions to the actual components that might be used to achieve such interfacing.

Now I’d go one step further, into the composition of the board itself.

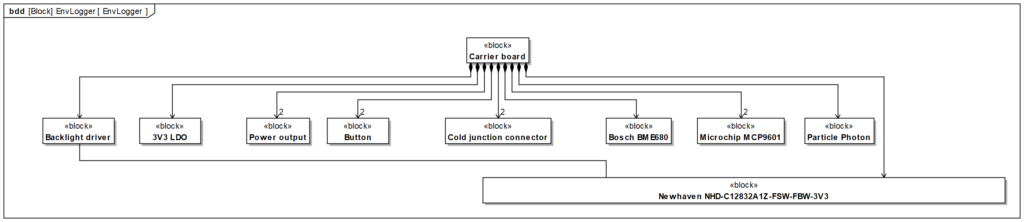

Display

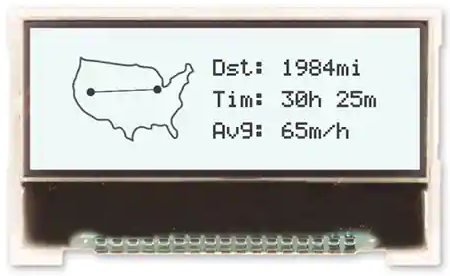

I like OLED displays, in particular the tiny 128×32 like this one. But, taken by a need for seeing the display directly attached to the board instead of being mounted on an intermediate carrier, I searched what Digikey had to offer and, to my disappointment, I didn’t find anything suitable.

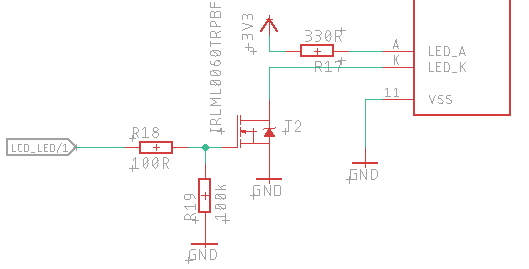

I ended up choosing a pretty standard FSTN LCD, backlit with white LEDs, 128×32 pixels: Newhaven NHD-C12832A1Z-FSW-FBW-3V3. SPI interface, 3V3.

The reason for the SPI interface was a lazy choice for speed. I didn’t even bother checking whether I could do everything with one single I2C bus since I had the interface available.

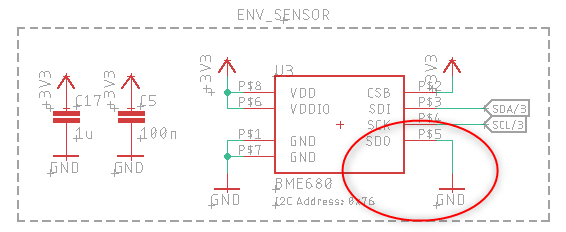

Environmental sensor

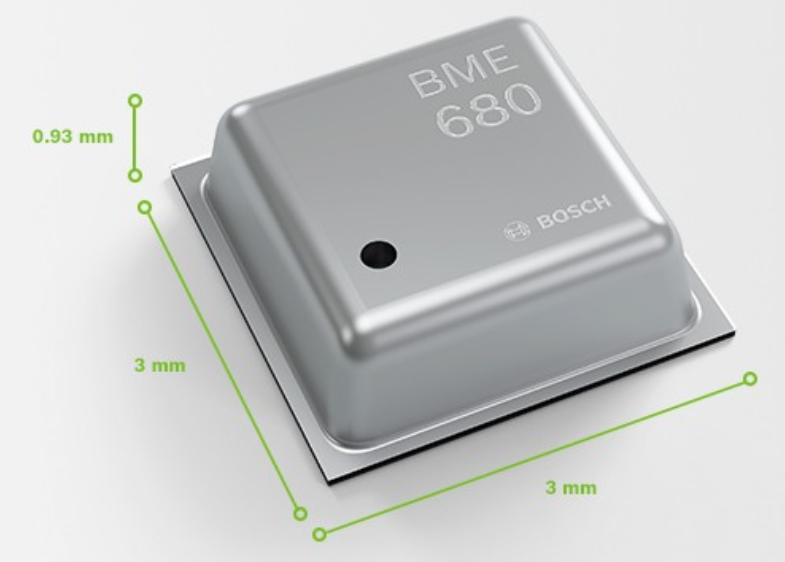

For a recent project it happened that I needed to keep constant track of the relative humidity in a room. I’m a fan of Bosch-Sensortec products and the BME680 was a perfect fit (besides its cost). It’s a little marvel: reliable and complete, offering sensing for:

- Temperature

- Relative humidity

- Atmospheric pressure

- VOC (volatile organic compounds)

The sensor speaks both I2C and SPI. I chose to use the former since I didn’t need bandwidth and because I decided that all the onboard sensors could had been suited conveniently by a single bus.

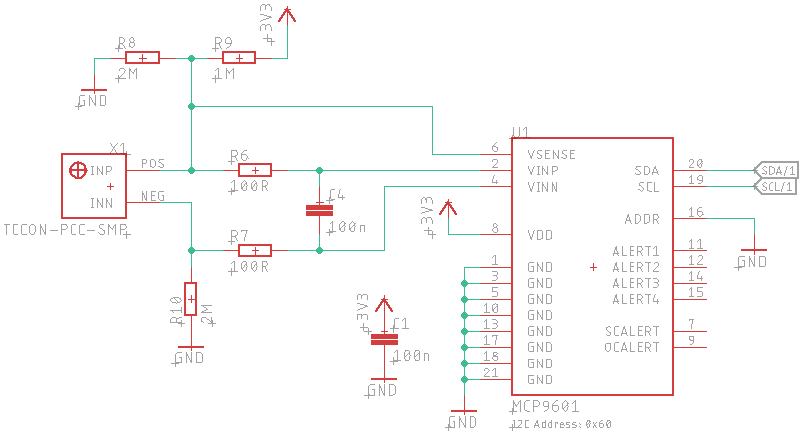

Thermocouple EMF converter

In two words, thermocouples generate an electromotive force which depends on the temperature difference between their two ends (hot and cold/reference junction). Wikipedia can shed a better light on the matter.

The whole point of measuring a temperature using a thermocouple, then, is to:

- Sample the detected EMF into a known quantity V

- Measure the temperature of the cold/reference junction Tref

- Apply some type-related adjustments E(T) (each type has its own characteristic function)

The result is E(Tsense) = V + E(Tref)

So, instead of doing all this, let’s find the right chip!

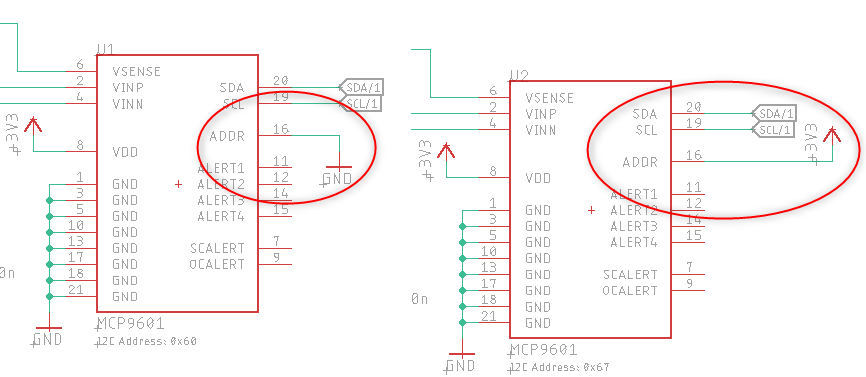

I don’t remember why I haven’t trusted Adafruit’s options for a thermocouple converter (such as the Maxim-Integrated MAX31855, which I’ve already used in the past) and ended up selecting the Microchip MCP9601, another pretty nice (and again, expensive) chip.

Such decision had probably to do with some kind of masochistic will to create an Eagle CAD part and to write a driver for it too (there’s nothing better to understand an ASIC than to talk to it).

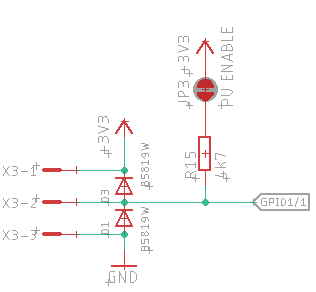

The circuit above shows the way the chip has been integrated:

- R6, R7, C4 form a low-pass filter

- R8, R9, R10 set up the open circuit detection

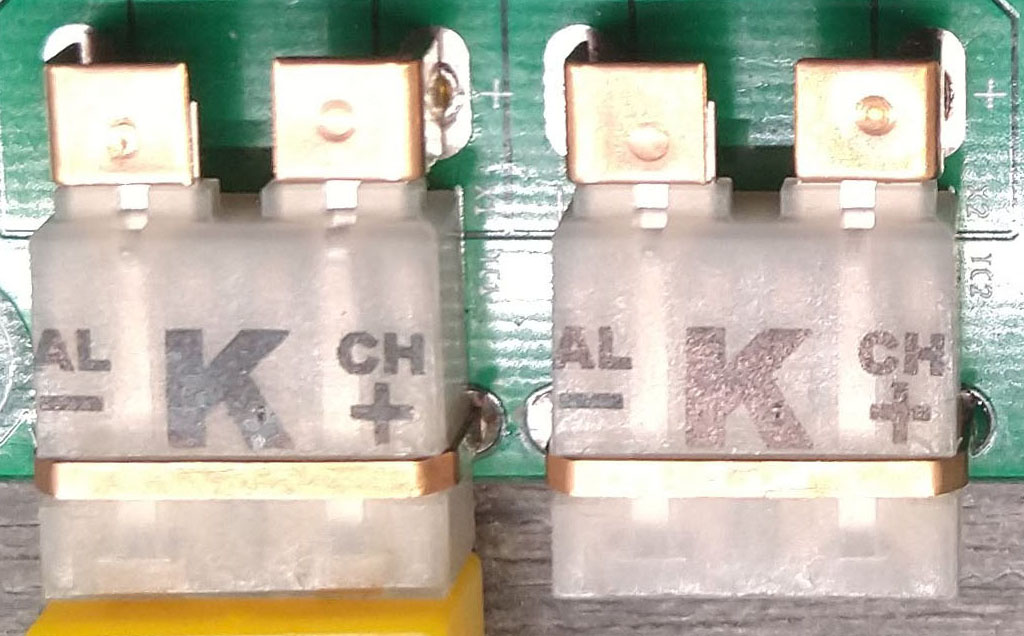

Thermocouples termination connectors

I had some hate for the standard “miniature” connectors for thermocouples. Probably because I have always had the bad luck to use loose receptacles. It’s not uncommon that a logging session had been jeopardized by a flaky connection, but I aimed to integrate them nevertheless in lieu of a brutal screw terminal.

Since these connectors act as terminator for the cold/reference junction, it’s quite vital that they have a minimal thermal resistance to the component that measures its temperature.

Searching for a proper option in Digikey didn’t yield much, besides a product distributed by Sparkfun, that gave me a new hopes for this connectors type. The one I ended up using is the Omega PCC-SMP.

These connectors are robust, they offer a copper bridge to prevent tilting and they have a satisfying (herculean) insertion force.

Type-K thermocouples are made of Chromel and Alumel (two Nickel-rich alloys) and their relative connectors (both plug and receptacles) are made of the same materials. The receptacles contact terminals end in copper stubs (as it can be seen in the picture above), soldered then to the board. That’s the so-called cold/reference junction and that’s the point that should be measured to get a reference readout.

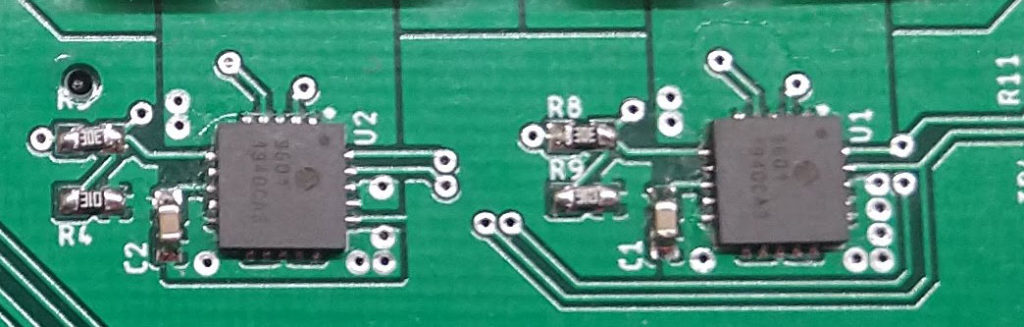

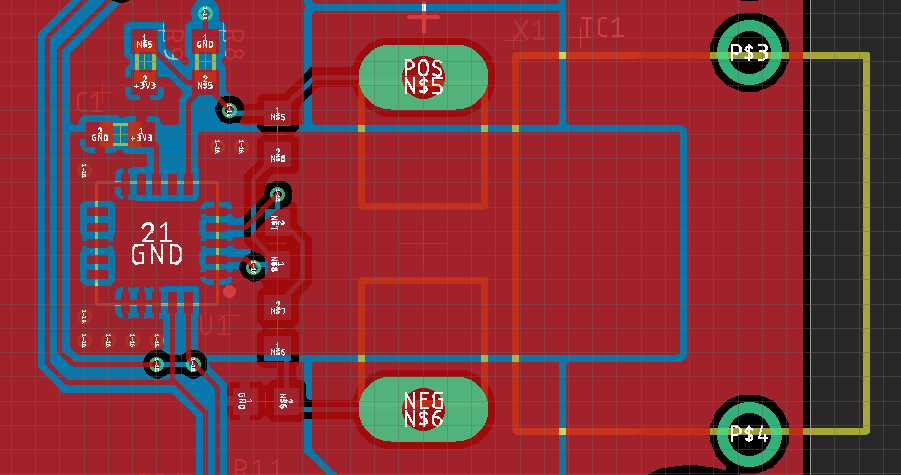

As shown above and by trying as much as possible to follow the guidelines described in the MCP9601 datasheet, chip and connector are placed in a way that tries to keep them close to each other, sharing copper planes to reduce their mutual thermal resistance (as described below, this doesn’t seem the case).

Power drivers

For the output drivers I chose two general-purpose 60V 116mOhm N-MOSFETs, namely the Infineon IRLML0060TRPBF and set them up in an open-drain configuration.

For the newbies (I’m among them, let me repeat the mantra): the series resistances R13, R14 limit the peak current that the gate tends to sink/source due to its capacitance during level changes, while the ones to ground (R21, R22) ensure that the gate charge is sunk when the OUT1/2 driving pins switch to high impedance, keeping the MOSFET at a determined (off) state.

The exact same setup has been also used for the backlight LEDs of the LCD.

Buttons and UI concept

Two buttons seemed to be enough for a minimal user interface. The reality is that even now I still don’t know for sure since I haven’t defined any specific user interaction model nor I have a storyboard.

Due to the potential flexibility of the device, I’m not sure if there will be only one firmware “to rule them all”, as opposed to the more probable approach where the firmware is prepared ad hoc and used for a specific scenario.

I’m not even that sure I’ll ever use them too..

Anyway the buttons are simple tactile SMD ones, nothing magic about them.

Extra inputs / GPIO

Since I’m using the DS1820 quite often and supporting them is no effort, I added two inputs, served by two three-pins Phoenix connectors that conveniently deliver power to the sensors too.

1-wire communication on these inputs can be enabled by shorting the solder bridge.

Power

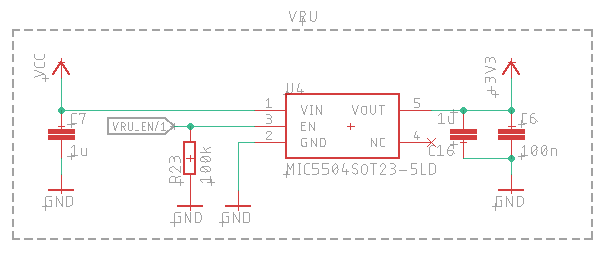

I didn’t want to use the Photon’s LDO VRU (the datasheet indicates a maximum allowance of 100mA), therefore I added a Microchip MIC5504 300mA LDO. The Photon is able to shutdown the power to the external devices via its enable pin.

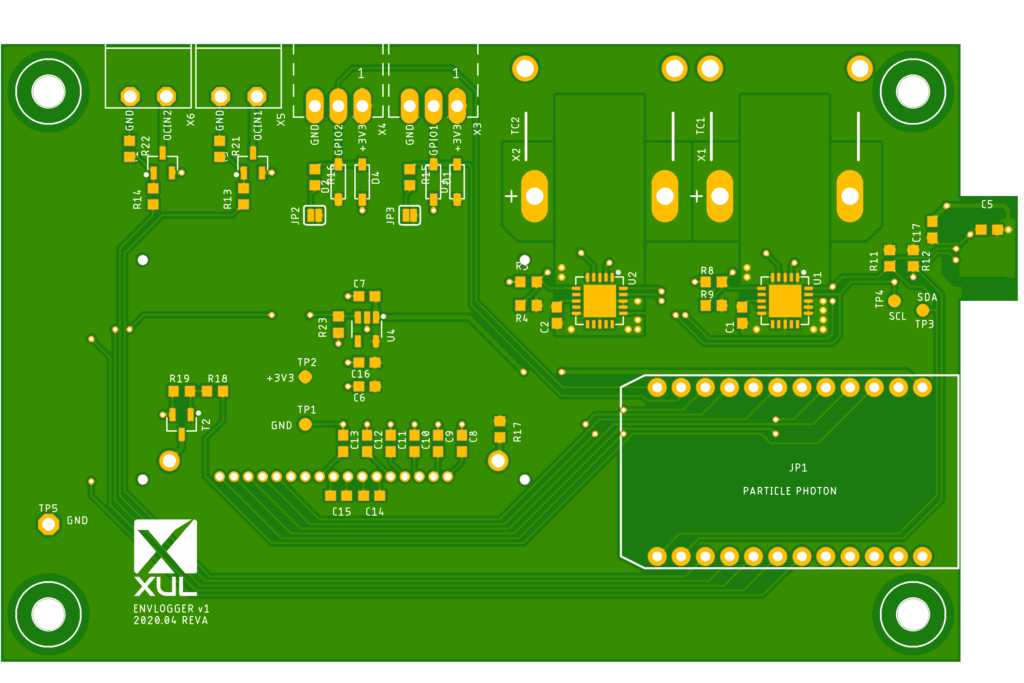

Schematics and PCB layout

One of the longest task I went thru was to create the missing components in Eagle CAD.

The most complicated unit was, surprisingly, the LCD. The dimensional drawings provided on the datasheet are lacking vital information, plus being plain wrong (the second drawing shows details of another unit). Since I was running the design in an lazy/express-high-risk-weekend mode, I didn’t have the unit at hand before designing the part (not a good practice, true).

But, then I found this repo, which I used to cross-check the footprint (kudos to the author).

The schematics didn’t pose any challenge, it was mostly following guidelines described by the datasheets and a bit of pins assignation scrambling (more about this later).

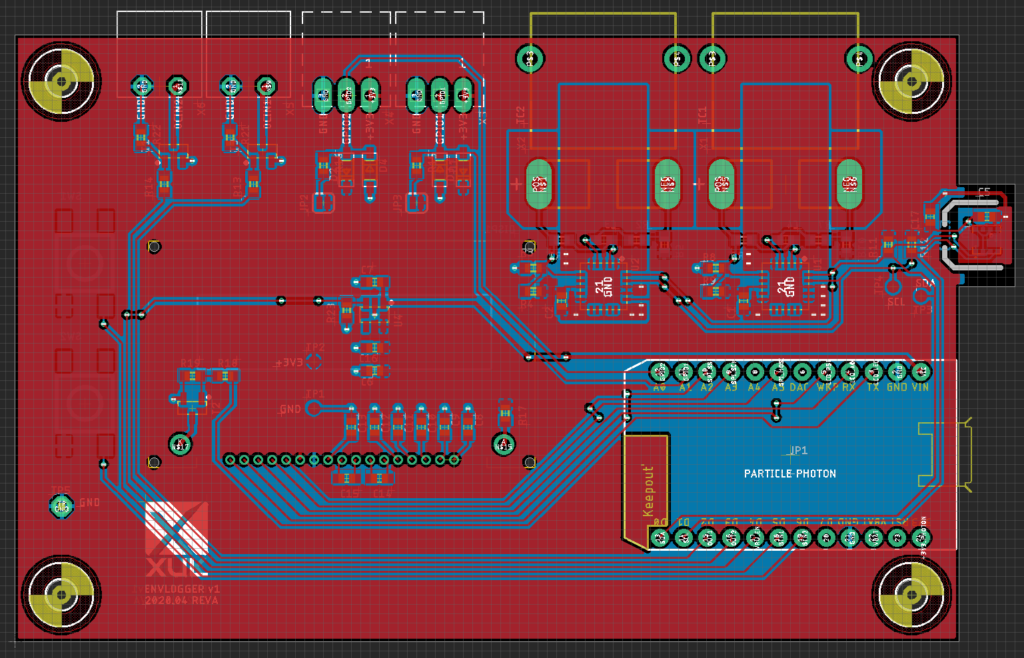

PCB layout

The PCB layout wasn’t complicated either. I followed some constraints such as:

- MCP9601 as close as possible to the connectors

- 3V3 VRU far from BME680 and MCP9601

- Photon on the edge to facilitate the USB connection

- BME680 as (thermally) isolated and exposed as possible

- Buttons on the right side of the LCD

Revision A ended up being a 2-layers standard 1.66mm FR4, 107mm x 65mm (yeah, those 7mm hurt), routed primarily on a metric grid.

The only relevant note is the funky shape due to the BME680 peering out. I just imagined an enclosure and that little tongue coming out of it. Similarly to the UI, this is another part where I should had invested a bit more, since Fusion360 was just invoking the Gods to be used.

Anyway, it’s not visible on the gerber rendered files, but the BME680 is trenched out to increase thermal insulation with the rest of the board.

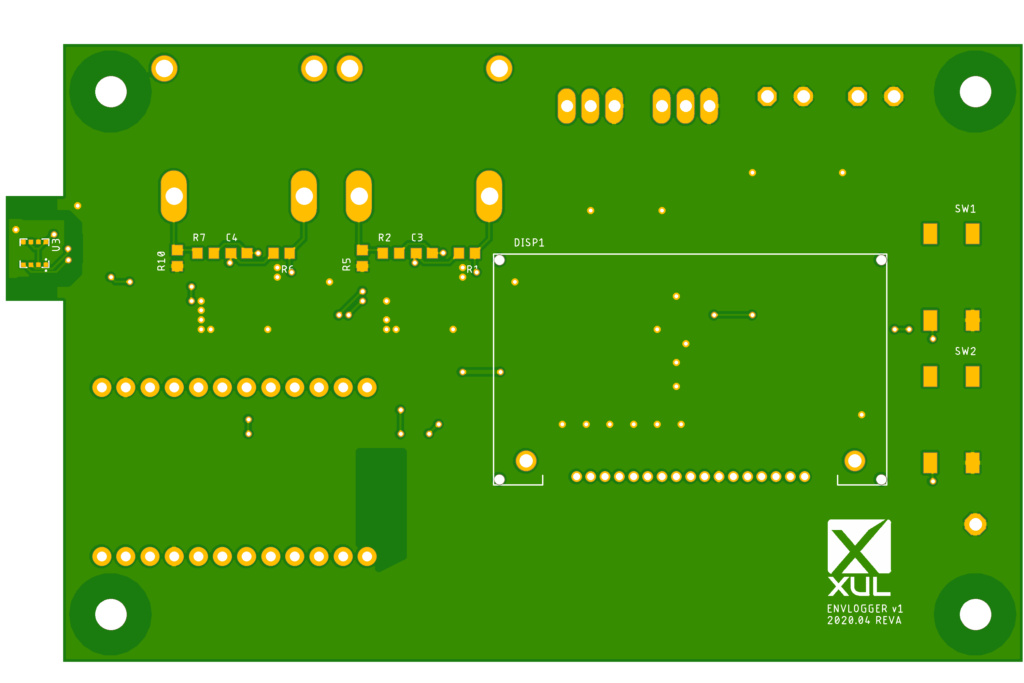

Ordering

I ordered the PCB from JLCPCB (not sponsoring). One week and the package was in my greasy hands, for a total 24,77€ (5 PCBs). I have been using their service quite often and I’ve never been disappointed and this price is just insane (considering that the cost of the service, excluding shipment, was 5,90€ and just because I exceeded the maximum size of the cheapest option by 7mm).

Soldering

I have the impression I badly wanted to prove my viper skills here as well, choosing 0603 passives and deciding that the BME680 had to be mounted to the bottom layer.

The reasons for both:

- Soldering 1206 components is piece of cake and a pleasant experience, but I started to stock 0603 passives since I use them quite often

- Bottom is supposed to be the side facing the user (the UI is there) so I imagined that exposing the sensor meant it to be on this side, having also the advantage to be on the opposite side of the active components

I didn’t reflow the whole PCB, since I wanted to practice air soldering for QFN and LGA. I was a bit worried to damage the BME680 without a proper soldering profile, but apparently it worked out pretty good, with just one soldering attempt per chip.

But reflow makes hell of a sense and having all the critical components on one side only would help a lot.

Issues

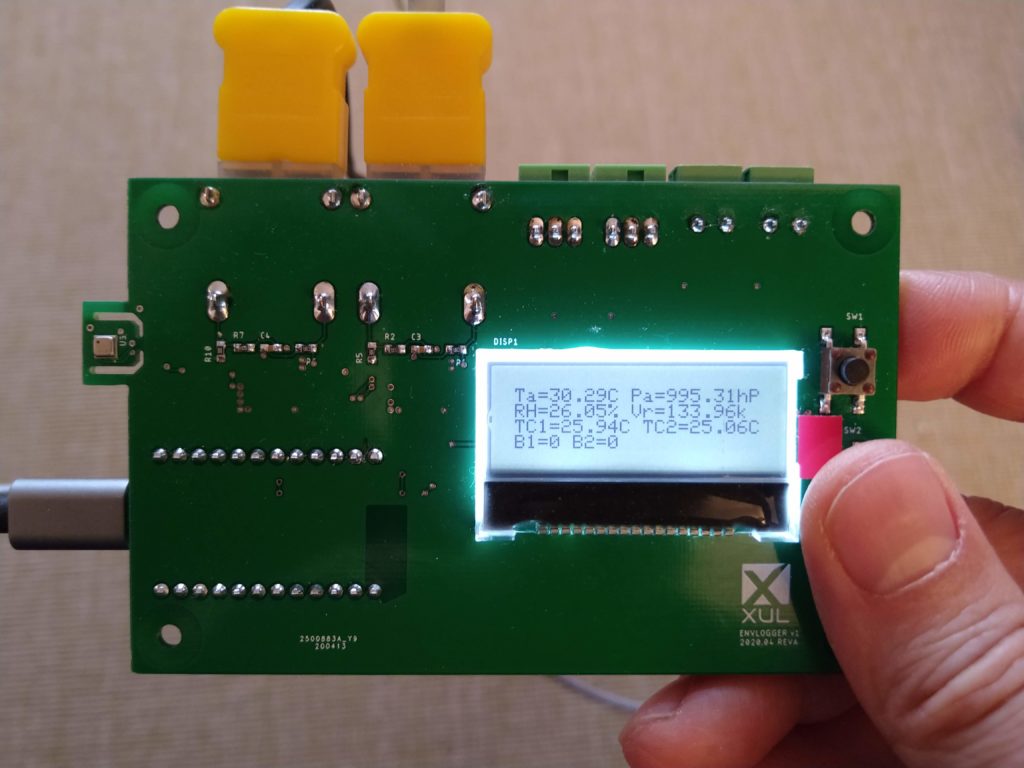

Well, first of all let’s say that the first (and only..) assembled board worked out completely fine without any trace-cutting and/or jumper wire.

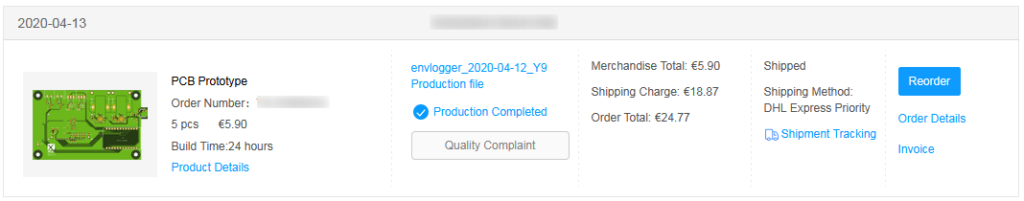

But there’s an annoying but foreseeable issue I didn’t take into account: the Photon board produces a relatively high amount of heat when operational. And this, so to say, is a problem.

Relatively to the BME680, I was taken aback by the rapid (~1 minute) ~+5C increase measured after powering up the device, but the picture above (where the VOC sampling was active) and the one below (where it wasn’t) cleared out the fact that the reason was the device’s self-heating. The device has an internal heater for the VOC sensor and it’s more than obvious that triggering it every second definitely contributes to a substantial increase of the temperature of the device itself.

On the other hand, it shouldn’t be a big deal for the MCP9601s, since the whole point of measuring the cold junction is to establish a reference point, right?

Yeah, sort of: there’s a slight temperature difference between the MCP9601s and the reference junctions (as shown in the picture below).

Anyway, the thermocouples disagree with the BME680 by just an average of 0,8C.

Probably an enclosure might help to equalize the heat. The orientation of the device also changes a lot the boundary conditions. Or maybe running the MCU and WiFi at their lowest power mode possible. Or maybe just redesigning the board? 🙂

Enclosure

A snug-fit case for the PCB can be found here: https://a360.co/4cl55LX

Print files can be also downloaded here: https://www.printables.com/model/913038-envlogger-v1-enclosure

Software and soft-related

Well, soft-related first:

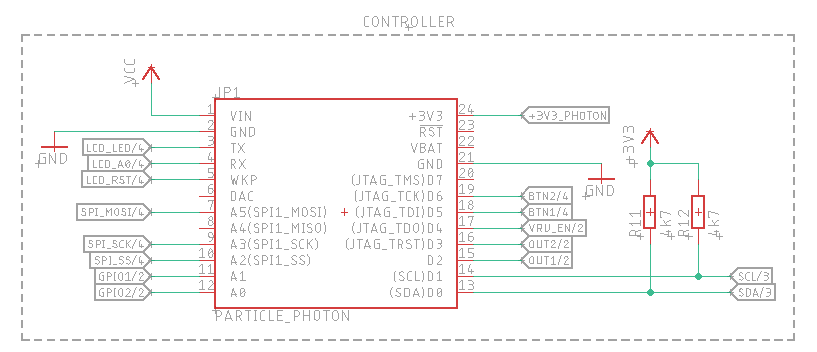

Pins and functions

Almost all pins are in use. The assignation logic here was:

- SPI1 to the LCD

- I2C for the sensors

- Backlight and outputs must be on PWM-capable pins (I love the fade-in of the backlight when the unit starts)

More information about the Photon can be found on its online datasheet.

Testing

The first bits of code I write are usually those that help to track issues on the design. Basically testing the functionality of each individual component placed on the board.

But a short digression in how the Particle units handle their operations.

Cloud particles and system modes

One interesting aspect of the devices offered by Particle is the incredible baseline equipment they’re delivered with to join the cyberspace. Devices can be maintained from a centralized console, firmware updates can be delivered OTA, events can be streamed and more.

Since the easiest starting point is to use their web IDE, I gave it a go.

I had been using a bit the IDE in the past for a couple of blinky tests, but this time I hit quite immediately its limits. Adding files is doable but not a snappy experience and it happened twice that for a classic “endless for loop” I ended up with a device that was unable to join the cloud again. No cloud, no OTA, no OTA no fix.

In spite of the fact that it’s quite easy to put the device in DFU and reflash a working nothingness, it shifts the attention from the Web IDE to a local setup (using the CLI tools), therefore I decided to switch to the local domain altogether using the Desktop IDE, based on VSCode.

I must admit I don’t like VSCode much. After hating Eclipse for years, it has become my best friend. Even if using Eclipse with Particle devices is somehow documented, the only guide I could find describes how to use it for SWD/JTAG debugging. I simply didn’t try.

(besides, I’m a vim-er, not an emacs-er, if anybody might ever be curious).

But then the next thing I’ve done was to switch the Photon to MANUAL system mode (no WiFi, no cloud by default). The cloud functionality is cool, but it slows down brutally the flash/test cycles.

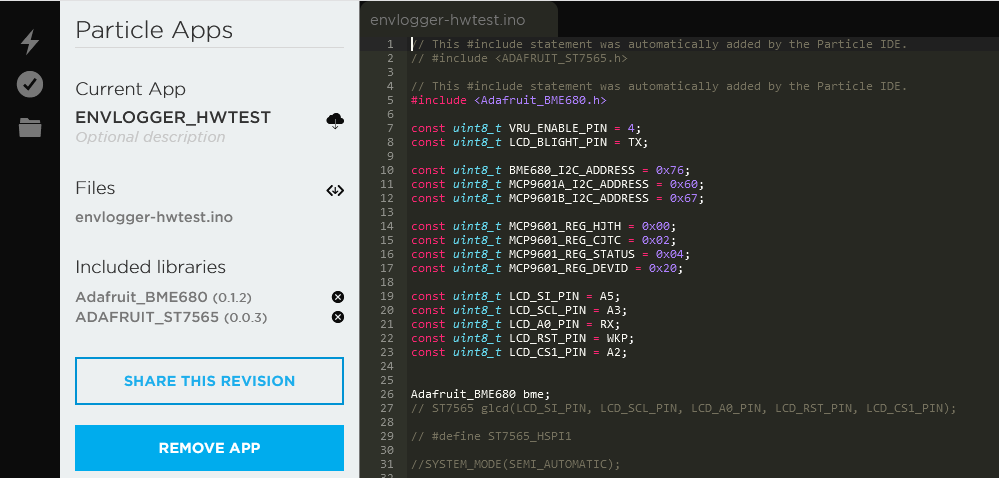

Testing the components

Needless to say that the very first thing I forgot is that without enabling the LDO VRU there was no juice for anybody. It’s a classic bad feeling when a short on VCC is going to ruin your day, but instead:

const uint8_t VRU_ENABLE_PIN = 4;

void enable_system_power()

{

pinMode(VRU_ENABLE_PIN, OUTPUT);

digitalWrite(VRU_ENABLE_PIN, HIGH);

delay(500);

}

And the 3V3 appeared on the test pads.

BME680

The BME680 is configured for I2C address 0x76 (SDO is connected to GND):

Testing the BME680 was the first, easiest task, since Adafruit provides a library (ported to Particle):

> particle library search BME680 particle-cli v2.5.0 Found 2 libraries matching BME680 Adafruit_BME680 0.1.2 12607 Library for running Adafruit BME680 on Particle Photon via I2C Adafruit_Jib_BME680 1.0.8 202 Library for running Adafruit BME680 on Particle Photon via I2C. Possibility to adjust Gas Sensor.

The gist of the test code is this:

void bme680_update()

{

if (!bme.performReading()) {

Serial.println("BME680: Failed to perform reading");

return;

}

String s;

s += "BME680: Ta=" + String(bme.temperature);

s += "C Pa=" + String(bme.pressure / 100.0);

s += "hPa RH=" + String(bme.humidity);

s += "% VCOR=" + String(bme.gas_resistance / 1000.0) + "kOhm";

Serial.println(s);

}

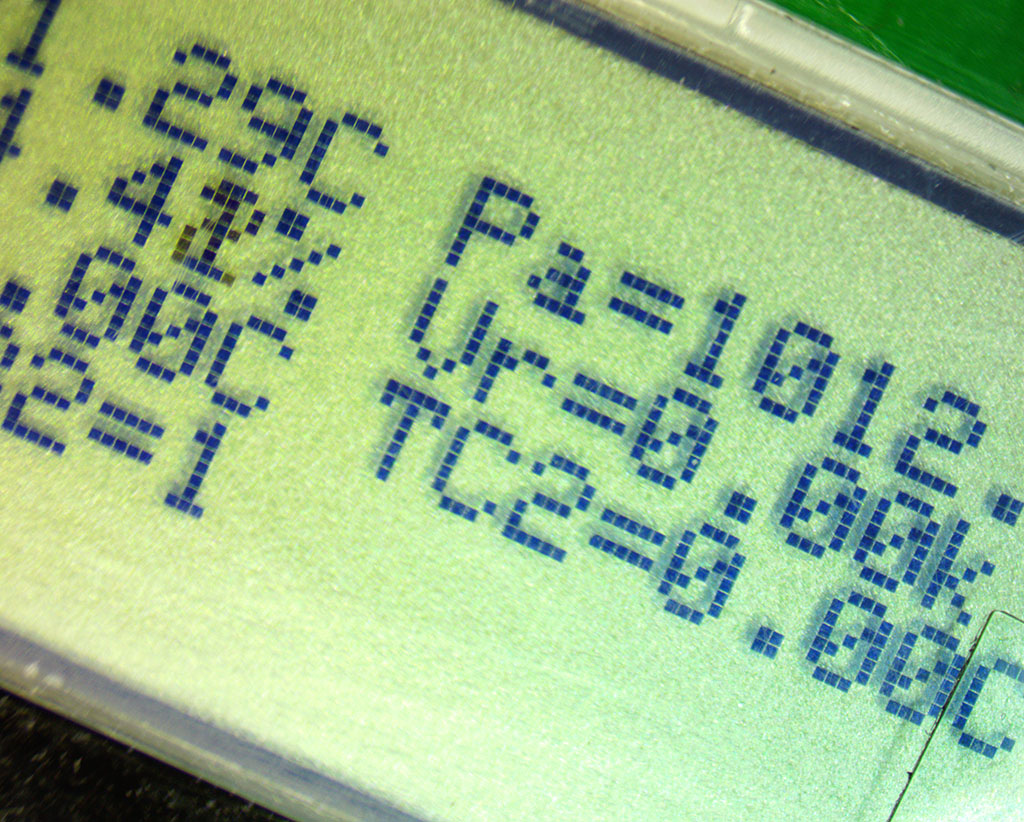

For this outcome:

> particle serial monitor Opening serial monitor for com port: "COM13" Serial monitor opened successfully: BME680: Ta=30.200001C Pa=995.390000hPa RH=32.077999% VCOR=211.831000kOhm

MCP9601

Either I didn’t spend enough time searching the matrix or once again the crave for reinventing the wheel lurked behind my neck, but I found no ready made libraries.

So I wrote the bare minimum for a test. Writing driver code is always helpful because it forces to read the datasheet thoroughly (it should be mandatory also when integrating the hardware, but..).

With the minimal set of read/write registers, the first thing to do was to query the devices for their IDs, essentially checking whether both units were operational. The first channel is set on address 0x60 (pin ADDR to GND) and the second on 0x67 (pin ADDR to VDD).

MCP9601: dev_id=0 dev_addr=60 id=41 rev maj=1 rev min=0 MCP9601: dev_id=1 dev_addr=67 id=41 rev maj=1 rev min=0

Pulling out data is then relatively easy, after adding the code to convert the short notation of the payload to an actual temperature.

I omit pasting the code here since it can be found on the repo.

Unfinished tasks: the open circuit detection didn’t work as I expected as well as the TH UPDATE bit on the status register. I’ll be back on it as soon as I’ll have more time to spend on the matter.

NHD-C12832A1Z-FSW-FBW-3V3 aka The LCD

This tiny display gave me a lot of headaches. Or better: its documentation did.

Anyway, this LCD is an assembly of a display and a display driver, namely the Sitronix ST7565R, originally conceived for monochrome 65×128 cellular LCD displays.

I started by using the Adafruit ST7565 library (ported for Particle) ending up with just a solid block of highly excited LCD pixels.

Then I had a look at the datasheet provided by Newhaven. Page 9 had what it seemed to be a sample implementation for an initialization routine, where very conveniently no information about the payloads is given. Since page 8 describes the command codes, I translated each payload to its relative command and annotated my code.

The display didn’t give any life sign and I had a limited set of options to understand what was the issue. So I dug a bit more in the ST7565R datasheet and started to feel a bit of frustration because this datasheet couldn’t be specific about the settings required for the display panel in use in the assembly.

So I went back to the Adafruit ported library and modified it to match the settings described in the display’s datasheet (and limiting the number of rows to 32):

$ diff ADAFRUIT_ST7565.h.orig ADAFRUIT_ST7565.h 34c34 < #define LCDHEIGHT 64 --- > #define LCDHEIGHT 32 $ diff ADAFRUIT_ST7565.cpp.orig ADAFRUIT_ST7565.cpp 404c404 < st7565_command(CMD_SET_BIAS_7); --- > st7565_command(CMD_SET_BIAS_9); 428c428 < st7565_command(CMD_SET_RESISTOR_RATIO | 0x6); --- > st7565_command(CMD_SET_RESISTOR_RATIO | 0x1);

And the display sprung to life!

The (test) firmware

The current firmware simply starts by initializing the devices and enters a loop where it polls the devices and prints the relative results to the display.

Having incorporated two buttons opens up a landscape of options in which such device might be able to do everything (logging, control) by just the mean of being configured to do so.

But before spending efforts on such solution, I find that it’d make more sense to implement specific patterns first (such as a simple datalogging setup for starters).

I’ll be sure to write updates on the matter 🙂

Words of wisdom

There are always lessons to be learned, even for such simple integration designs.

What I find relevant to be remembered (yeah, some are part of the baseline requirements, I reckon):

- One never stops learning

- Employing devices that could achieve high precision requires careful, experienced design

- Purpose and usage patterns of a device should be evaluated way before completing the design

- Thoroughly reading datasheets is not an option but a must

- Achieving perfection is utopian, as well as getting things right at the first attempt. But it’s always good to start from something and have the patience to persevere and iterate

Fail or iteration?

And here the sweet gist: nothing comes out of the world of the ideas without a pinch of effort and unscathed by errors.

Finding the sweet spot between expectations, fuel (determination, budget) and capabilities is and always be an exciting challenge.

Iteration is the key: fail and retry. It’s hard to say when it’s good enough and it’s usually the end user the last judge to this process..